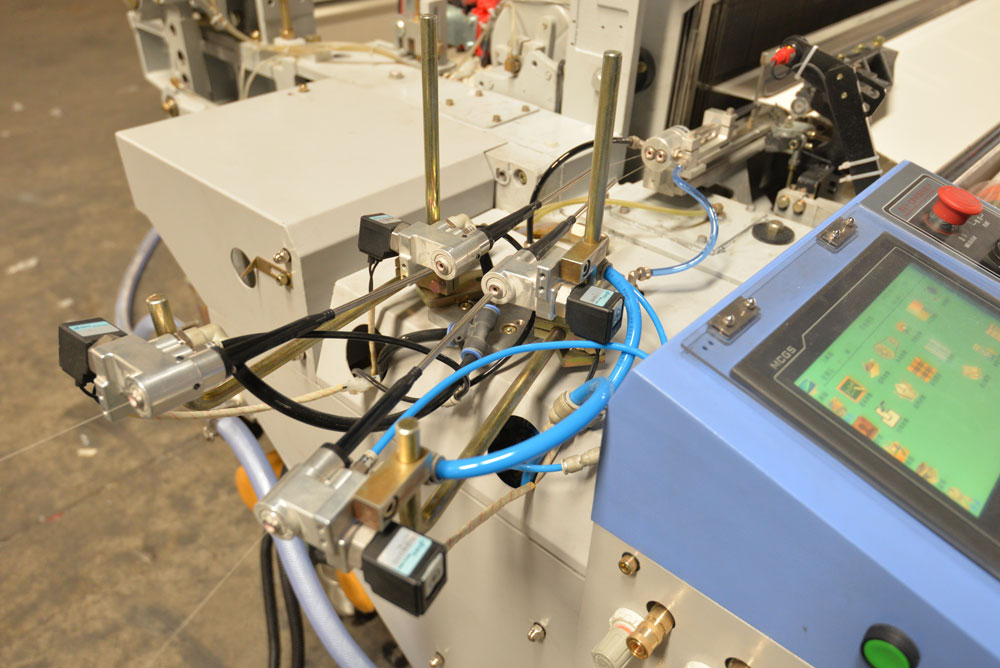

How to set the main nozzle and auxiliary nozzle of an air jet loom

2023-09-11

chinaredflag

The setting of the spraying angle of the main nozzle should consider the clarity of the opening of the left warp yarn. If set too early, it will cause warp hanging, causing an increase in weft stop. If set too late, it will cause weft shrinkage and other defects at the edge of the fabric. It is necessary to increase the spraying pressure. If the opening of the left warp yarn is good, the spraying angle can be appropriately advanced to save gas. Generally, the spraying end angle is 180 ° ± 15 °.

2. What is the effect of main nozzle pressure on weaving?

When the pressure of the main nozzle is too high, the arrival time of the weft yarn is advanced, and the weft yarn head end will be blown or broken, resulting in phenomena such as weft shrinkage, loose weft, and short weft at the edge of the fabric. The left edge of the fabric is not well folded, and the scissors are not cut neatly.

3. How to set the injection time of the auxiliary nozzle?

The spraying time of the first group of auxiliary nozzles is generally the same as that of the main nozzle, or about 10 ° earlier, and the ending angle is about the starting spraying angle+80 °. Depending on the type of weft yarn, in order to obtain sufficient weft insertion speed, the spraying angle of the first group of auxiliary nozzles can be appropriately extended. The spraying angles of other auxiliary nozzles are generally postponed by 15 ° to 20 ° in order, and the ending angle is the starting spraying angle+80 °. In actual production, the injection angle is advanced, which can reduce the consumption of air compressor.

4. What is the impact of the pressure of the auxiliary nozzle?

When the pressure of the secondary nozzle is too high, the weft yarn reaches earlier, which is easy to be blown off and increases air consumption; When the pressure of the auxiliary nozzle is too low, the arrival time of the weft yarn is delayed, which is prone to weaving defects such as weft shrinkage and short weft. Moreover, the poor flying state of the weft yarn can cause unreasonable stoppage of the platform.