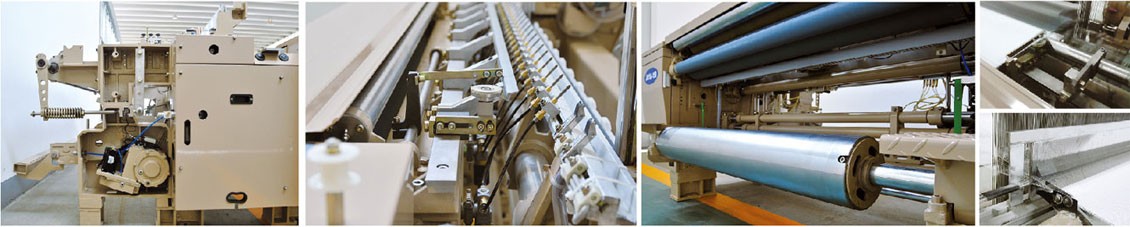

JA92-GF glass fiber air jet loom is designed for weaving glass fiber

fabric,suitable weaving varnished cloth,laminated fabric etc. which are

based on the primary material of glass fabric.This loom suitable weaving

light,middle,heavy fabric,can weaving light glass fabric blew

50g/㎡,also can weaving heavy glass fabric above 300g/㎡.with the feature

of small weft abrasion,large output,good quality,stable operation,low

noise,so it is have a good price advantage for user.

JA92-GF glass fiber air jet loom with crank shedding ,also can with cam

shedding,4-8 shafts;with the combined of single nozzle,main and

auxiliary nozzle and profile reed,solenoid valve control weft insertion;

four-lever beating-up mechanism;full automatic continuous positive

double backrest electronic let-off;mechanical take up;separating out

machine take-up,with independent servo-drive,automatic control

tension,the biggest diameter of take up can reach 1000mm,mechanical

cutter,photoelectric weft feeler device;strong absorption of the device

effectively to attract the textile fiber which the loom work

produces,Guarantee workers'physical and mental health.

Main features :

1. Overall advantages: special design for glass fiber weaving. precision manufacturing. carefully assembly fine glass fiber special air jet loom, to ensure the stability and superiority of product quality.

2. Selvedge cuttef mechanism adopt chopper mode, drag pad can rotate along the cloth surface, and its surface is uniformly worn to improve the service life and cloth selvedge unify.

3. Selvedge waste yarn collection mechanism: waste yarn completely inhales the suction box. saves waste yarn. makes the cloth edge neat, avoids the cloth edge defect, reduces the yarn consumption, avoids the hairiness to cause the air pollution. guarantees the machine clean and good Working environment.

4. Constant tension batching mechanism: fabric tension is controlled by sensor, which can guarantee the constant tension and high quality of cloth. Air expansion roller can be used for special varieties.

5. Pressure-regulating system: main air pressure can be adjusted automatically according to the weft arrival, which can reduce the weft breaking rate, beneficial to improve the weaving efficiency and reduce the gas consumption.

6. Professional designed big warp beam and big batching mechanism reduce the number ofdoffing and corresponding increase weaving efficiency, flange diameter: 1000mm. the maximum diameter of the batching cloth: 1200 mm.